Leave Your Message

The automotive industry demands efficient and reliable tools. An Inground Scissor Lift stands out among vehicle lifting solutions. This equipment offers various benefits for both professionals and hobbyists.

When you choose an Inground Scissor Lift, you gain accessibility and safety. Its low-profile design allows easy vehicle entry. This lift design avoids clutter in service areas. Mechanics can work comfortably without obstructions. However, some may overlook maintenance. Regular checks are essential to maximize performance.

An Inground Scissor Lift also offers versatility. You can lift various vehicle types, from compact cars to trucks. This adaptability can boost your workshop's productivity. Despite these advantages, it requires careful planning and investment. High initial costs can be intimidating, but the long-term benefits are significant. It's worth weighing your options thoughtfully.

Inground scissor lifts are vital for modern automotive repair shops. They offer numerous advantages that enhance efficiency. Space-saving design is a significant benefit. These lifts are installed below the ground, freeing up valuable floor space. Mechanics can move around easily, improving workflow and accessibility.

Another key advantage is the stability they provide. When a vehicle is lifted, it remains secure. This is crucial for safety during intricate repair jobs. Technicians can work confidently, knowing the car won’t shift unexpectedly. Additionally, these lifts often have adjustable height options. This feature allows for better ergonomics, reducing fatigue during long hours of work.

While the benefits are clear, installation is often tricky. Proper planning and precise measurements are essential. A poor installation could lead to future complications. Regular maintenance is also necessary. Neglecting upkeep can result in reduced efficiency and safety risks. It's a continuous commitment to keep the lift in optimal condition. Balancing these factors is important for any shop owner.

In the world of automotive lifts, inground scissor lifts stand out. They offer a unique advantage over traditional two-post or four-post lifts. These lifts are built into the ground, providing unobstructed access to the underside of vehicles. This makes it easier to perform maintenance tasks. Mechanics can work without hindrance from the lift arms.

Comparing inground scissor lifts to other types reveals distinct features. While two-post lifts require space for their arms, inground options save room. This allows for more vehicle storage and workspace. However, installation can be complex and costly. Not every garage has the setup for such lifts. You also need to consider the maintenance involved.

Moreover, scissor lifts offer a stable lifting platform, crucial for safety. But if not calibrated correctly, they can become a hazard. Users need to be cautious about weight limits and floor structure. Just like any equipment, they require regular checks. Balancing benefits against challenges is key when choosing a lift type.

When considering an inground scissor lift for automotive needs, several key features stand out. The lifting capacity is paramount. Many lifts can safely elevate vehicles up to 10,000 pounds or more. According to recent industry reports, the demand for lifts capable of handling heavy-duty vehicles is increasing. This trend highlights the need for durable models that can withstand frequent use and heavy loads.

The size of the lift platform also plays a critical role. A wider platform offers more stability and can accommodate various vehicle types. Features such as adjustable width can enhance versatility, allowing service for everything from compact cars to SUVs. Additionally, look for lifts with safety features like automatic locks and anti-sway systems. These ensure both operator safety and vehicle protection during maintenance.

**Tips:** Always check the installation requirements of the lift. Not all facilities have the same space or ground structure. Regular maintenance checks are necessary to keep the lift functioning correctly. Evaluate your specific requirements to select the right scissor lift. This can be an area where mistakes often occur. Choosing the wrong model may result in safety risks or inefficiencies. Careful consideration can save time and prevent costly errors in the long run.

When considering an inground scissor lift for automotive needs, safety and maintenance are crucial. Regular inspections are essential to ensure everything is functioning properly. Look for signs of wear or damage. Hydraulic systems often require fluid checks and the occasional topping up. It’s vital to adhere to maintenance schedules to avoid unexpected downtime.

Safety should be a top priority. Operators must be trained properly to avoid accidents. Using safety locks is a good practice. If a lift malfunctions, quick reflexes may be necessary. Accidents can happen, so having a contingency plan is wise. Operators should understand emergency procedures well.

While inground scissor lifts offer convenience, they demand responsibility. A lack of proper maintenance can lead to severe issues. Inspect the lift daily before use. Is the area clear of hazards? Could someone potentially trip? Being vigilant helps create a safer environment. Remember, the goal is to enhance productivity while ensuring safety for everyone involved.

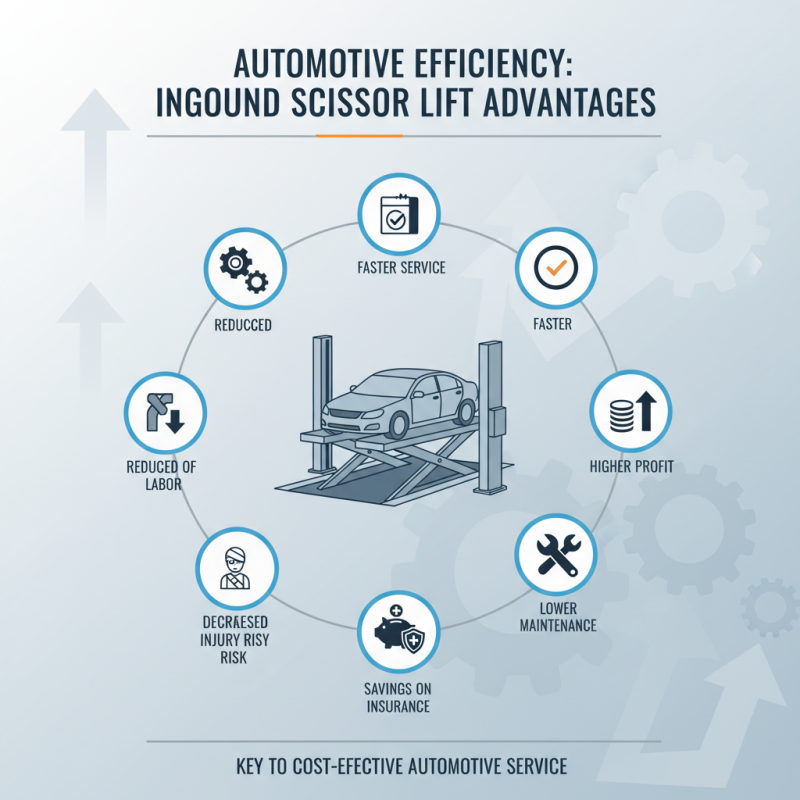

In the automotive industry, efficiency is key. An inground scissor lift offers significant cost-effectiveness. These lifts minimize the need for excessive labor, cutting down service time. Lower operational costs lead to higher profit margins. Many businesses discover they can save on maintenance, too. Using these lifts can lower the risk of injury, which in turn saves insurance costs.

Tips for choosing the right lift: Consider the weight capacity you need. Analyze the space in your workshop. Make sure to check the power requirements as well.

Keep in mind, not all inground scissor lifts are created equal. Some may require more installation time than expected. Assessing the long-term benefits is crucial. Don’t rush this investment; reflect on your specific needs. Investing wisely can make all the difference in operational efficiency. Embrace the advantages of efficiency with careful planning.