Leave Your Message

When it comes to lifting heavy vehicles, the right equipment is crucial. A high-quality Scissor Floor Jack can make all the difference. The demand for such jacks has surged, fueled by the increasing need for safe and efficient vehicle maintenance. According to industry reports, the automotive tools market is projected to reach $14 billion by 2027, emphasizing the vital role of jacks in the repair process.

Choosing the best Scissor Floor Jack involves examining several factors. Lifting capacity, stability, and ease of use are essential metrics. A jack that fails to lift securely poses risks, as evidenced by recent studies showing that improper jack use contributes to accidents in garages. Some jacks may lift efficiently but lack durability, leading to regrets after just a few uses.

While many jacks promise high performance, not all deliver. Those seeking the best options must carefully review specifications and user feedback. Many jacks might not meet expectations, leading to wasted time and frustration. Prioritizing quality over price is often the wiser choice for ensuring safety and reliability on every lift.

Scissor floor jacks are essential tools for lifting vehicles safely. They work using a simple yet effective mechanism that relies on a scissor-like design. When you crank the handle, it raises the base through a series of linked arms. This configuration offers stability and strength. The lifting power is impressive for its size.

Many users often overlook maintenance tasks. Neglecting to lubricate the joints can lead to rust. A rusted jack may fail during use, risking safety. Regular checks ensure everything functions smoothly. Some might forget that a heavy load can exceed limits. Each jack has a specific weight capacity. Ignoring this can cause accidents or damage to the jack itself.

Understanding your scissor jack is vital. Each part plays a role in the performance. The lifting arms need to be sturdy. Users should also consider their workspace. An uneven surface could lead to tipping over. Familiarity with the mechanism enhances safety and efficiency.

When selecting a scissor floor jack, several key features should be considered. Load capacity is critical. Most scissor jacks can safely lift 2 to 3 tons. However, it is essential to ensure that the chosen jack meets your specific lifting needs. A jacks's lifting height also plays a significant role. Many models offer a range from 3 to 19 inches. Selecting the right height ensures safety while working under vehicles.

Durability is another essential feature. Look for jacks made from high-quality materials. Steel construction is common, providing necessary strength and longevity. The average lifespan of a well-built jack can exceed 10 years with proper maintenance. However, some designs can rust or weaken, prompting necessary reflection on their upkeep.

Consider ease of use as well. Features like quick-lift technology can save time and provide convenience. Yet, some users find that these systems may require extra force. An ergonomic handle can also enhance usability. Weight and portability are other factors to ponder. A lighter model can be easier to maneuver, but it might compromise stability. Always remember, finding the perfect balance is crucial for both performance and safety.

When it comes to lifting power, scissor floor jacks are a reliable choice. These jacks can lift heavy loads with minimal effort. Industry data shows that a quality scissor jack can manage up to 3 tons. This capacity is important for automotive tasks where safety and durability are paramount. Regular maintenance can extend the lifespan of these tools.

One key factor to consider is the lift height. Many scissor jacks have a range of 14 to 20 inches. This range allows for versatile applications. However, some users find that the lower lift height limits their functionality. The design should also promote easy storage. A compact model can save space in your garage or workshop.

Material quality plays a significant role in performance. Steel jacks generally offer better durability than those made from lighter materials. Moreover, users often overlook the importance of weight distribution. An uneven load can compromise safety. Understanding proper usage is crucial. Many users fail to follow guidelines, leading to accidents. Regularly reviewing these practices can improve overall safety and effectiveness.

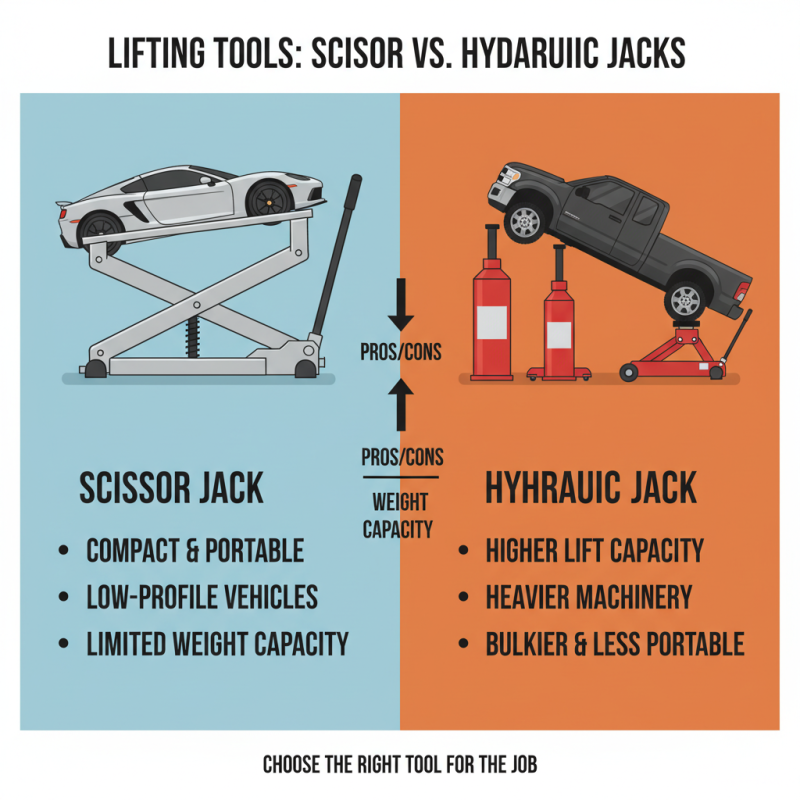

When comparing scissor floor jacks to other lifting tools, several factors stand out. Scissor jacks are compact and easy to maneuver. They are ideal for low-profile vehicles. However, they can only lift a limited weight. This aspect is crucial when considering heavier machinery. Other tools, such as hydraulic jacks, often provide more lifting capacity. Yet, hydraulic models can be bulkier and less portable.

Scissor jacks are usually simpler in design. They require less maintenance than hydraulic counterparts. However, the operation can be labor-intensive. Users often find themselves cranking for extended periods. In contrast, pneumatic jacks provide speed but can be costly. The efficiency of scissor jacks can be appealing for those on a budget. Still, their limitations in height adjustment can be frustrating.

A comparison of user experiences highlights some issues. Some users report that scissor jacks wobble under high weight. Stability becomes a concern during lifting. Other tools may not have this problem. Yet, they come with their own challenges, such as complicated setups. Ultimately, each lifting tool has its strengths and weaknesses. Finding the right one requires careful consideration.

Using scissor floor jacks requires attention to safety. Understanding their mechanics is crucial. Scissor jacks amplify force, but incorrect usage can lead to accidents. The National Institute for Occupational Safety and Health (NIOSH) reports that improper lifting techniques cause many injuries each year.

When using a scissor floor jack, make sure it's on a flat surface. This ensures stability and reduces the risk of slipping. Before lifting, inspect the jack for any visible defects or signs of wear. It’s also essential to read the manufacturer's guidelines for weight limits.

Always utilize jack stands after raising a vehicle. Relying solely on the jack poses severe risks. The Department of Transportation (DOT) emphasizes that most accidents occur due to insufficient supports. Lastly, never work beneath a car supported only by a scissor jack. Quick moments of negligence can lead to devastating consequences. Stay alert and prioritize safety always.